Are You Ready

For the Future of

Construction?

The construction market is changing from old techniques and materials to a modern, efficient and eco-friendly concept, where time and money cannot be wasted…

Money Saver & Time Effective

Steel frames are not affected by moisture, eliminating dry time delays. With minimized delays from weather, as snow, rain or heat, METALLEVE system reduces the construction time, which means saving money.

Precise and Flexible

CNC manufactured, steel panels are built with precisely cut and assembled studs. Also, the inherited steel characteristics makes it perfect for architectural challenges like curved spans or pre-made doors and windows.

Durable and Safe with a Long Lifespan

With an exceptional resistance to fire, corrosion and pests, steel framed buildings are the first choice for extreme environmental conditions.

1-3 Hour UL Assemblies

Steel frame panels can accommodate to any UL assembly that can be met using metal stud framing, allowing for complete design flexibility.

About Us

Metalleve Wall System was created by Jonathan Barcelos and his brother, Lucas, after more than 20 years working in the construction business in New England.

Jonathan, former Supervisor with Nauset Construction and CEO of Ontime Construction Services, is since long time, a great fond of metal structures and partition walls to be used in construction.

Being an entrepreneur by nature, after a long period of study, Jon decided that the time had come to put this new idea and technology into practice: start a company to fabricate and assemble metallic panels for the walls, both interior and exterior.

And Metalleve Wall System started!

Why Metalleve Cold Formed Steel?

- Money saving alternative

- Building time saver – 75% faster

- Exterior and interior load bearing walls, exterior curtain/by- pass walls and interior partitions entirely prefabricated with metal stud panels

- Complete solution for commercial and residential buildings

- Floor trusses in several depths and spans to fit your project

- Roof trusses in a different profiles and sizes

- Blocking trusses

- ICC Certified and meet IBS codes 2009, 2012, and 2015

Years Experience

A New Solution for a New Market

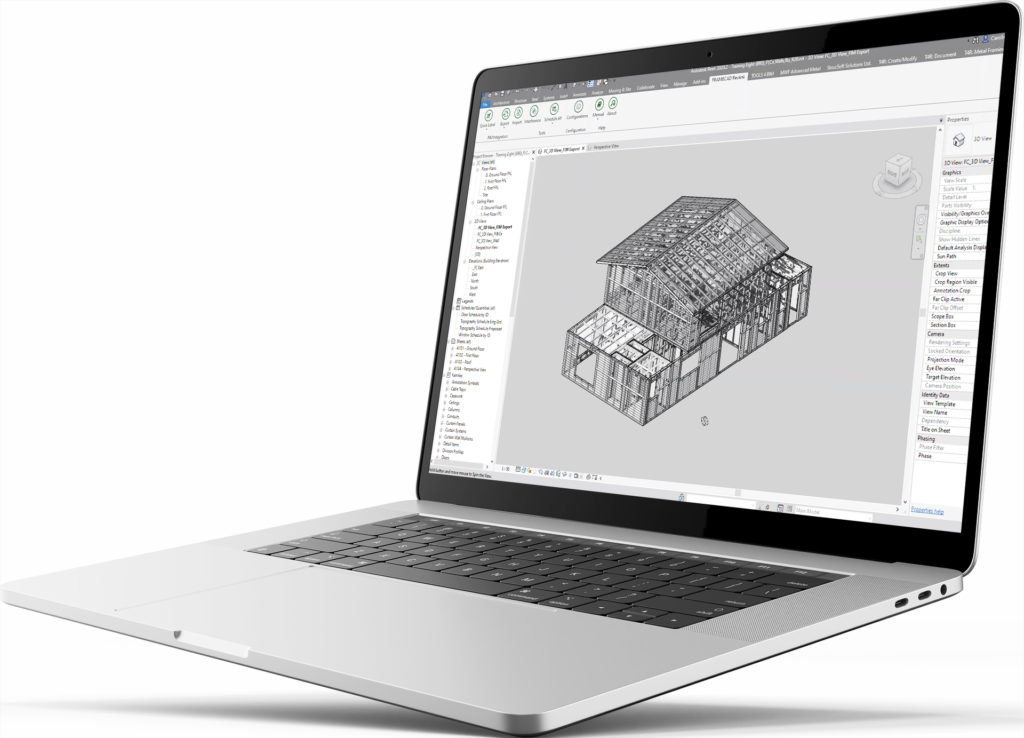

We Use a Last Generation Software to Create our Buildings

- Fast: Typically doing over 25,000 calculations per square meter of roof and walls in seconds; a task which would take days, or potentially weeks, if done manually.

- Accurate Producing: Accurate calculations automatically, eliminating errors that may occur during manual calculations.

- Reduces Engineering Costs: Providing real-time engineering as the building is designed; this reduces the engineering input and means that external engineering costs are greatly reduced.

- Straightforward: We tackle the difficult tasks, enabling non-engineering designers to play a more significant role in the design process.

- Reduces Material Costs: Using material as efficiently as possible and reducing wastage. The material savings from using METALLEVE System can be as much as 30% on roof truss designs by optimizing, and value engineering.

- Compliant: Making real-time engineering calculations as the designs are created, analyzing loads, deflections and other forces, and making it an easy process to check for compliant engineering.

A Technological System Helps Us to Build With Performance

A rapidly high performing solution for producing framing and trusses in heavy residential and light commercial buildings. The F450iT has been designed to handle the heavy gauge steel required to construct 1 to 7 story structures and outputs 3-5/8” and 6” profiles. Suitable for heavy high walls, heavy trusses, heavy flooring and short span flooring; The framing product produced by the F450iT is a boxable section, making assembly for heavy building requirements easier. The F450iT offers full framing capabilities with 11 tooling punches and the option of an additional custom tool (on request at time of purchase of manufacturing system).

Benefits of Metalleve System

• Taking a design-led approach to construction revolutionizes your approach to human resources, changing the roles and tasks that specific people undertake dramatically.

• Designers can be easily trained and are fully supported by METALLEVE to use the design process and software

• Highly specialized engineers aren’t needed for significant portions of the process, cutting down on costly consultant resource

• As the decision-making is moved to the design stage, the design process is less reliant on having many highly skilled builders on-site

• Local, unskilled labor can be used to better effect – local labor forces can be easily trained to use the METALLEVE System and to erect framing on-site, creating local job opportunities and reducing human resource costs.

• With CFS construction, compliance is no longer such an immense pain point – CFS systems like METALLEVE make the compliance process easy.

• All commonly followed building codes are included instead of prebuilt into METALLEVE System, with the ability to add other codes as necessary

• Ensuring your project is designed to standard simply means choosing the correct code from a dropdown menu and making sure you look out for any flagged issues

• Engineers only need to be brought in after the team is confident that the project is up to standard

• Engineering plans are unlikely to be rejected, but changes can be made easily and quickly if needed, avoiding costly project delays.

- Metalleve Structures can typically reduce engineering costs by up to 80% per ton and save up to 30% on design, engineering, and resource costs.

The compliance process is sped up due to Metalleve Structures taking into consideration local design standards.

Resource consent issues don’t hold up the process – any changes can be integrated without having to start from scratch, saving engineering time and reducing the costs of using qualified engineering resources.

By following pre-determined shop drawings and guiding markings on frames and other materials, erection on-site is sped up considerably.

• Reducing waste has both financial and environmental implications and CFS construction is extremely effective in doing so.

• Waste can make up 20% of materials on a traditional construction project – the equivalent of wasting one building out of every five constructed.

• With the METALLEVE system, waste is reduced to less than 3% of the materials used, reducing costs and the environmental impact.

• Construction uses only what is needed – every part is used, and every frame is designed in the most efficient way possible.

• Because the unused materials are steel, wastage can be sold to specialists to be melted down and used elsewhere.

• In all aspects of construction, maximizing ROI is key. With CFS construction, time, human and material resources are all reduced, improving ROI significantly.

• Engineering time and costs reduced, while still ensuring a quality output, thanks to METALLEVE capabilities.

• Human resources are used more efficiently, including the utilization of unskilled, local labor.

• Every aspect is planned in advance, resulting in the manufacturing of only what’s needed and reduced wastage costs.

• Changes are integrated quickly at low cost, ensuring projects remain on time and under budget.

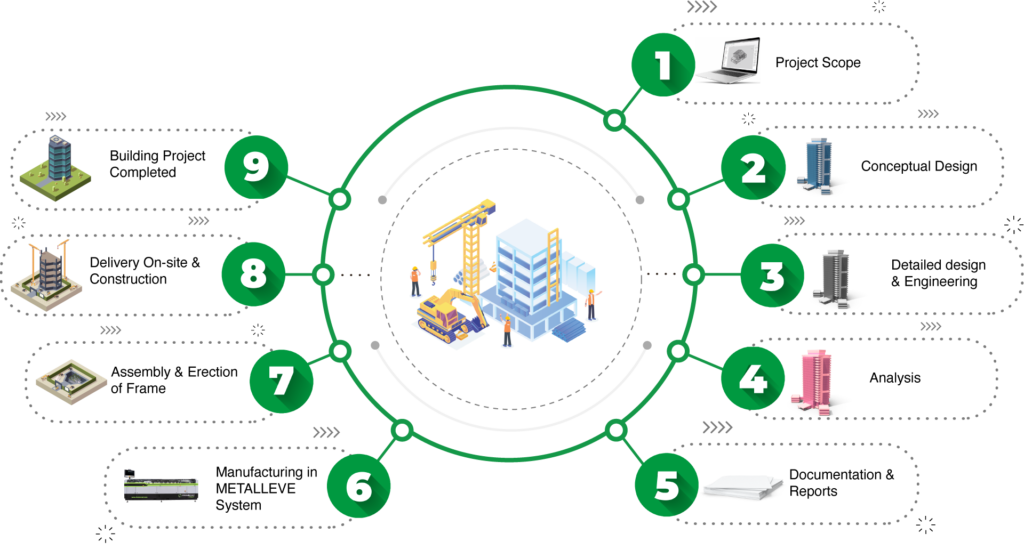

Our Work Process

Project Scope

Conceptual Design

Detailed design & Engineering

Analysis

Documentation & Reports

Manufacturing in METALLEVE System

Assembly & Erection of Frame

Delivery On-site & Construction

Building Project Completed

Metalleve in action

Play the video and find out more about Metalleve Production Factory.

Check out how Metalleve system look’s

Are You Ready To Build the Future With Us?

Send us a Message

Copyright © Metalleve 2021. All Right Reserved.

Developed by Me Veja Na Web.