NuFacade’s panelized construction system revolutionizes building practices with its efficient and environmentally friendly approach. Utilizing pre-fabricated components, it allows for swift assembly and minimal disruption on construction sites, significantly accelerating project timelines while reducing waste. This system incorporates high-quality materials and manufacturing standards to ensure exceptional thermal performance and aesthetic appeal, making it a top choice for sustainable and visually appealing construction projects.

Speed of Assembly

Once the components arrive on-site, the construction process speeds up significantly because the panels are designed to be quickly and efficiently assembled.

Reduced Waste

Fabricating components off-site allows for tighter control over materials, significantly reducing waste generated during the construction process.

Improved Quality Control

The controlled environment of a factory allows for greater oversight and precision in the manufacturing of panels, leading to better build quality and fewer defects.

Energy Efficiency

Panels can be designed with integrated insulation and airtight sealing measures that significantly enhance the building’s energy performance once installed.

NuFacade Panelized Wall Systems

The NuFacade panelized construction system offers a suite of advantages that significantly enhance modern building practices. First, the speed of assembly is greatly increased due to the pre-fabricated nature of the components, allowing for rapid on-site construction that maintains high standards of quality. This method not only accelerates project timelines but also reduces disruptions during the building process. Additionally, the use of pre-fabricated materials leads to a substantial reduction in construction waste. Since all components are precisely made to measure and produced under controlled factory conditions, material efficiency is optimized and excess waste minimized. Quality control is another critical benefit, as the controlled manufacturing environment ensures all components meet stringent standards before they reach the construction site, effectively reducing the likelihood of defects. This level of precision in the production phase ensures a high-quality final product. From an energy efficiency perspective, the integration of specialized materials such as high performance sheathing, ROXUL insulation, and high-performance windows significantly enhances the thermal performance of buildings. This system is also equipped with a vapor-permeable air barrier that not only protects against moisture ingress but allows the building to breathe, optimizing indoor air quality and energy efficiency. Moreover, aesthetic integration is seamlessly achieved with the use of Ceraclad siding and precision-engineered panels. This ensures that buildings not only perform well but also have a modern and visually appealing exterior, enhancing both their curb appeal and functional longevity. These combined features make NuFacade’s panelized construction system a superior choice for efficient, sustainable, and aesthetically pleasing building projects.

Key Components and Brands Used:

- Cold Formed Steel Studs: Metalleve Wall Systems provide structural components and facade panel layouts. Metalleve specializes in pre-fabricated steel stud wall panels and complete rainscreen systems, delivering these components directly to the site. The collaboration ensures high-quality outputs that are consistent and up to the structural demands of the project.

- Structural Insulated Sheathing: Fibre Reinforced Cement Composite (FRCC) panels are used in the system for their durability and excellent thermal properties. Mineral wool insulation, such as ROXUL or equivalent brands, is used for stud wall infill. This sheathing provides superior fire resistance as well as strong thermal and acoustic insulating performance.

- Windows: High Performance 76mm Softline uPVC windows with triple-pane glazing are selected to enhance energy efficiency and provide high-quality, durable window solutions.

- Air and Moisture Barriers: 3M‘s 3015VP Vapor Permeable Air Barrier is used to ensure that the building envelope is tightly sealed against air and moisture ingress.

- Firestop System: Siderise CW-FS Perimeter barrier along with fixing brackets and foil tape are employed to meet stringent fire safety standards.

- Exterior Cladding: Ceraclad fiber-cement siding is chosen for the exterior, providing a modern aesthetic with a triple-coated, caulk-free rainscreen system that offers additional protection from the elements.

Installation Process

Preparation and Framework Setup: The installation begins with the preparation of the building’s facade. This includes cleaning and assessing the existing structure for any necessary repairs or modifications to ensure it can support the new panel system. Fero hanging brackets are anchored to the building’s exterior. These brackets are crucial for the subsequent attachment of panelized components, providing a secure and adjustable method to align the panels accurately.

First Layer Panel Installation: Aluminum angles are set up to receive the first layer of panels. These angles are secured to the facade and are critical for supporting the panels. The first layer of panels is then installed, beginning from the base and moving upwards. Panels are attached using Tek-screws from both underneath and above, ensuring a tight fit and alignment.

Second Layer and Insulation: Once the first layer is securely in place, a second layer of panel frames is added. This layer slides behind the exterior layer and is attached with screws from the exterior. The cavity between these panel layers is filled with soft insulation, enhancing the building’s thermal resistance. The type and thickness of the insulation are chosen based on energy efficiency requirements and building code regulations.

Integration of Windows and Special Features: Window openings are pre-cut in the panels, with specific types such as Amberline Single Operable or Double Operable windows installed as per the architectural specifications. Special attention is paid to ensure that windows are seamlessly integrated into the panel system, with proper sealing and insulation around the window frames to prevent thermal bridges and air leaks.

Finishing and Sealing: After all panels and windows are in place, the installation is finished off with caps and sealing materials to protect against weather elements and to ensure the longevity of the installation. Each joint and seam between panels is sealed to enhance the airtightness of the facade, crucial for maintaining the building’s energy efficiency.

Quality Checks and Adjustments: Throughout the installation process, periodic checks and adjustments are made to ensure alignment, level, and adherence to design specifications. This includes the use of laser levels and plumb lines to check the verticality and horizontality of the panels. Final inspections are conducted to confirm that all elements are correctly installed and functioning as intended, with a particular focus on the building’s improved thermal envelope and overall aesthetic appeal.

The installation process is meticulously planned to ensure that each component fits perfectly, maintaining the aesthetic continuity of the building while upgrading its performance and sustainability.

A New Solution for a New Market

Project Highlight: Salem Fairweather

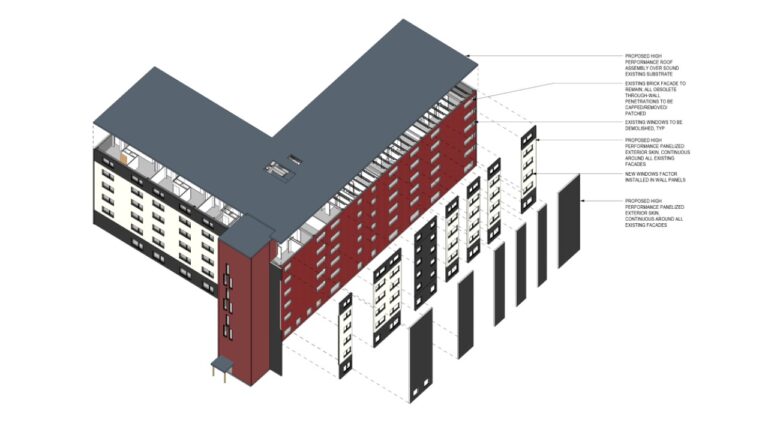

The Salem Fairweather Project is a pioneering initiative focused on transforming existing buildings into paragons of sustainability and energy efficiency through the use of NuFacade’s advanced panelized construction systems. Central to this project is the off-site fabrication of critical building components like walls and facades. These elements are precisely engineered and assembled in a controlled factory setting, which ensures high quality and uniformity. After fabrication, these components are transported to the project site for swift, efficient assembly, drastically reducing construction waste and minimizing disruption to residents. The panelized systems are designed to seamlessly integrate with the existing structures, enhancing the buildings’ thermal envelope and significantly improving their energy performance. Alongside this, the project incorporates high-performance air and water barriers to protect against environmental elements, further boosting the durability and energy efficiency of the buildings. Through these innovative construction techniques, the Salem Fairweather Project sets a new standard for retrofitting processes, demonstrating the transformative potential of panelized construction in revitalizing older buildings to meet contemporary energy and sustainability standards.

Check out how Metalleve system look’s

Are You Ready To Build the Future With Us?

Send us a Message

Copyright © Metalleve 2021. All Right Reserved.

Developed by Me Veja Na Web.